一般来说,判断一个产品是否可以开模进行注塑,应该遵循以下思路:产品外观及要求→结构→开胶→脱模,这是为什么呢?下面分析。

Generally speaking, to judge whether a product can be opened for injection molding, the following ideas should be followed: product appearance and requirements → structure → glue opening → demoulding. Why? The following analysis.

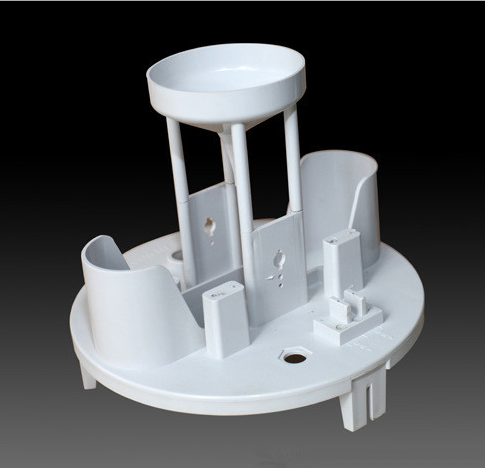

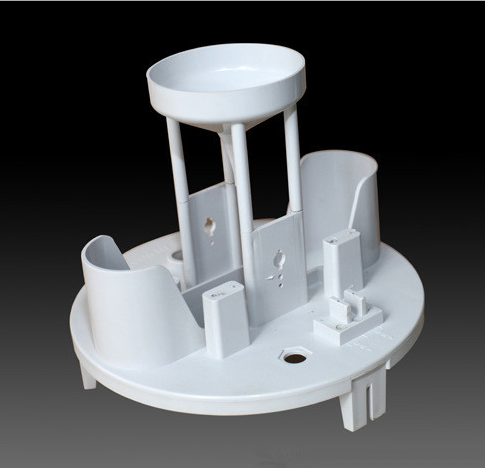

以某产品为例,在整个设计过程中,各种因素引起的思维变化导致模具设计结果的变化太大。拿到这款产品后,我们来看看它的主要信息。图中,红色圆圈全部倒置。产品为装饰条,外观件。除模具结构外,不允许损坏外观。

Taking a product as an example, in the whole design process, the change of thinking caused by various factors leads to the change of mold design results. After we get this product, let's take a look at its main information. In the picture, the red circles are all upside down. The products are decorative strips and appearance parts. The appearance shall not be damaged except for the mold structure.

这部分产品有很多小回升,脱模方向都是一样的。因此,请考虑在滑块上进行。左右两侧的小侧孔为底切,拔模分析显示的两侧分型面正好在外观面上。为保证美观,左右两侧应将整面视为一个整体滑块。

There are many small recoveries in this part of products, and the demoulding direction is the same. Therefore, please consider on the slider. The small side holes on the left and right sides are undercut, and the two side parting surfaces shown in the draft analysis are just on the appearance surface. To ensure aesthetics, the left and right sides shall regard the whole surface as an integral slider.

分型不能与拔模分析所示位置一致,应包到产品底部,之所以在这里包含它,是因为如果模具生产时间长了,模具磨损了,或者模具没有匹配好。分型面位置容易产生毛刺,我们将产品分型移到里面。如果这里出现毛刺,不会影响整个产品的质量,是一个看不见的位置。

The parting cannot be consistent with the position shown in the draft analysis. It should be wrapped to the bottom of the product. The reason why it is included here is that if the mold production time is long, the mold is worn, or the mold is not well matched. The position of the parting surface is easy to produce burrs, so we move the product parting to the inside. If there is burr here, it will not affect the quality of the whole product. It is an invisible position.

本产品的浇口有两个比较好的地方选择,如下图箭头所示。如果是在里面制作,由于中间位置没有倒置,所以可以用作潜浇口或喇叭浇口,而不会增加模具的难度。而且,做内侧可以大大减少模具的偏心。因此,浇口应选择在里面比较合适。

There are two good places to choose the gate of this product, as shown by the arrow in the figure below. If it is made inside, because the middle position is not inverted, it can be used as a submerged gate or a horn gate without increasing the difficulty of the mold. Moreover, making the inner side can greatly reduce the eccentricity of the die. Therefore, the gate should be properly selected inside.

山东模具制造厂家认为可以在这里做一个斜屋顶可以留出更多的空间。前模加一套顶针板是合理的选择。为保证开模时能充分,使受力点不作用在斜弹力工字上,我在前模顶出板底部加了弹力胶,使弹簧失效或挂钩间隙都令人担心。禁止限制可降低风险并满足我们所需的模具要求。

Shandong mold manufacturers believe that a sloping roof can be made here to leave more space. It is a reasonable choice to add a set of thimble plates to the front die. In order to ensure that the mold can be fully activated during mold opening, so that the force point does not act on the oblique elastic I-shaped, I added elastic glue at the bottom of the front mold ejection plate, which makes the spring failure or hook clearance worrying. Prohibition of restrictions can reduce the risk and meet the mold requirements we need.

前模升降器的一部分位于两个外滑块下方。如果将左右大滑块用作后模滑块,则前模升降器和后模滑块将在开模方向上发生位移。模具完全打开后,升降器停留在前模中并与后模分离。合模时,前模斜顶必须与分型面同步,否则会撞到模具。

A part of the front mold lifter is located under the two outer sliding blocks. If the left and right large sliders are used as the rear mold sliders, the front mold lifter and the rear mold sliders will shift in the mold opening direction. After the mold is fully opened, the lifter stays in the front mold and is separated from the rear mold. When closing the mold, the inclined top of the front mold must be synchronized with the parting surface, otherwise it will hit the mold.

因此,产品两侧的整体大滑块必须做成前模斜弹簧或斜顶,以保证同步。左右两边的斜弹都变成了斜顶,但也不是完全斜顶,上面是被钩子拉着的。倾斜炸弹的顶部装有弹簧。

Therefore, the overall large sliding blocks on both sides of the product must be made into the front mold inclined spring or inclined top to ensure synchronization. The oblique shells on the left and right sides have become inclined roofs, but they are not completely inclined roofs. They are pulled by hooks. The top of the tilting bomb is equipped with a spring.

每次拿到新产品,都应该按照这个思路进行。这应该是一个合格的模具设计师应该有的想法或思维导图。到这里,基本上理清思路了,左右两侧做弹簧,中间位置做前模斜顶。所以说产品能不能注塑加工模要遵循一定的思路,这样会使得工作顺利很多,您可以关注我们的网站

www.sdlqmj.com查看更多相关信息!

Every time you get a new product, you should follow this idea. This should be an idea or mind map that a qualified mold designer should have. At this point, we have basically clarified our thinking. We will make springs on the left and right sides, and the inclined top of the front formwork in the middle. Therefore, whether the product can be injected into the mold or not should follow certain ideas, which will make the work much more smooth. You can pay attention to our website www.sdlqmj Com for more information!