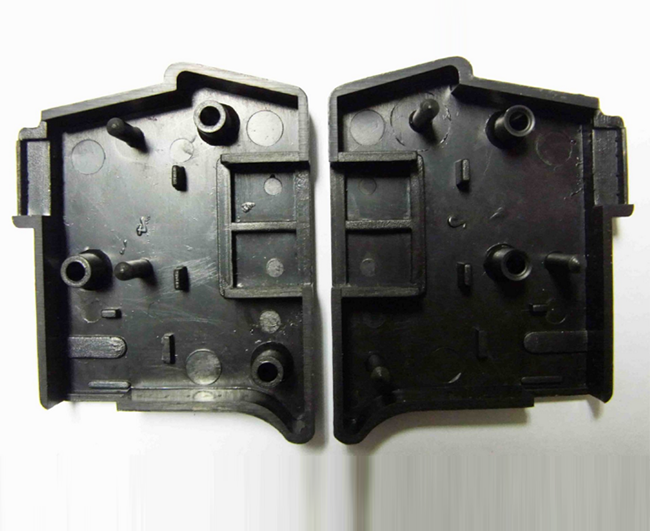

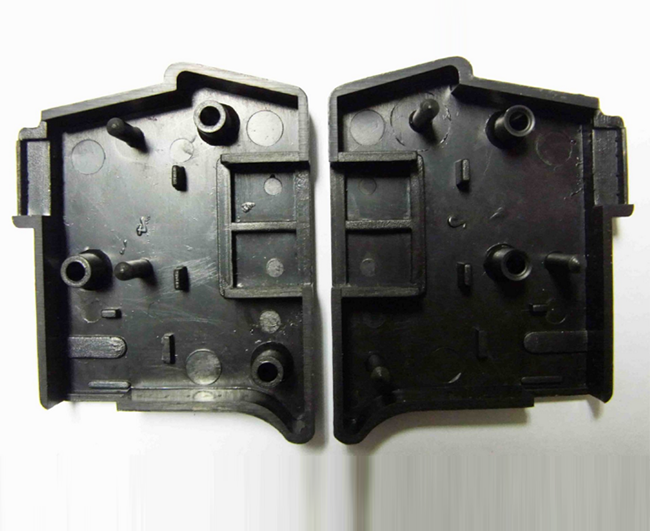

塑件的外部和内部形状是由型腔和型芯直接成型的,这些复杂的立体型面加工难度比较大,特别是型腔的盲孔型内成型表面加工,如果采用传统的加工方法,不仅要求工人技术水平高、辅助工夹具多、刀具多,而且加工的周期长。

The external and internal shapes of plastic parts are directly formed by the cavity and core. It is difficult to process these complex three-dimensional surfaces, especially the blind hole internal forming surface of the cavity. If the traditional processing method is adopted, it requires not only high technical level of workers, many auxiliary tools and tools, but also a long processing cycle.

激光盘记录面的粗糙度要达到镜面加工的水平的0.02-0.01μm这就要求山东模具制造厂家的模具的表面粗糙度达到0.01μm以下。长寿命注塑模具对于提高高效率和降低成本是很必要的,目前注塑模具的使用寿命一般要求100万次以上。

The roughness of the recording surface of the laser disk shall reach 0.02-0.01 of the level of mirror machining μ M this requires that the surface roughness of molds manufactured by Shandong mold manufacturers reach 0.01 μ M or less. Long life injection mold is necessary to improve efficiency and reduce cost. At present, the service life of injection mold generally requires more than 1million times.

精密注塑模要用刚度大的模架,增加模板的厚度,增加支承柱或锥形定位元件以防止模具受压力后产生变形,有时内压可以达到100MPa。

The precision injection mold should use the mold base with high rigidity, increase the thickness of the template, and increase the support column or conical positioning element to prevent the deformation of the mold under pressure. Sometimes the internal pressure can reach 100MPa.

顶出装置是影响制品变形和尺寸精度的重要因素,因此应该选择佳的顶出点,以使各处脱模均匀。高精度注塑模具在结构上多数采用镶拼或全拼结构,这要求模具零部件的加工精度、互换性均大为提高。

Ejection device is an important factor affecting product deformation and dimensional accuracy. Therefore, a good ejection point should be selected to ensure uniform demoulding everywhere. The structure of high-precision injection mold mostly adopts inlay or full assembly structure, which requires the processing accuracy and interchangeability of mold parts to be greatly improved.

对于注塑件而言,大多是与其它零部件配套组成完整的产品,而且在很多的情况下都是在其它部件已经完成,急切等待注塑件的配套上市。因为对制品的形状或尺寸精度要求很高,加之由于树脂材料的特性各异,模具制造完成后,还需要反复地试模与修正,使开发和交货的时间非常紧张。

For injection molded parts, most of them form complete products with other parts, and in many cases, other parts have been completed, eagerly waiting for the supporting products of injection molded parts to be listed. Because of the high requirements for the shape or dimensional accuracy of products, and the different characteristics of resin materials, after the completion of mold manufacturing, it is necessary to repeatedly try and correct the mold, which makes the development and delivery time very tight.

山东模具制造厂家提醒您,模具制造不是终目的,而是由用户提出终制品设计,模具制造厂家根据用户的要求,设计制造模具而且在大多数情况下,制品的注射生产也在别的厂家。这样就造成了产品的设计、模具设计制造和制品的生产异地进行的情况。

Shandong mold manufacturers remind you that mold manufacturing is not the end goal, but the end product design proposed by the user. Mold manufacturers design and manufacture molds according to the requirements of users. In most cases, the injection production of products is also in other manufacturers. In this way, the product design, mold design and manufacturing and product production are carried out in different places.

模具生产批量小,一般属于单件的生产,但是模具需要很多的标准件,大到模架,小到顶针,这些不能也不可能只由一个厂家单独完成,且制造工艺复杂,普通设备和数控设备使用不均衡。

The production batch of molds is small, which generally belongs to single piece production. However, molds need many standard parts, ranging from mold base to thimble. These can not and cannot be completed by only one manufacturer. Moreover, the manufacturing process is complex, and the use of ordinary equipment and CNC equipment is uneven.

The above is the relevant content about the problem shared for you today. I hope it can help you. If you want to know more, you can contact us by phone or follow our website http://www.sdlqmj.com 。